Technical solutions

VECO France offers the fabrication of different types of custom metal parts with different techniques such as electroforming and chemical cutting.

VECO technical solutions for the fabrication of your metal parts

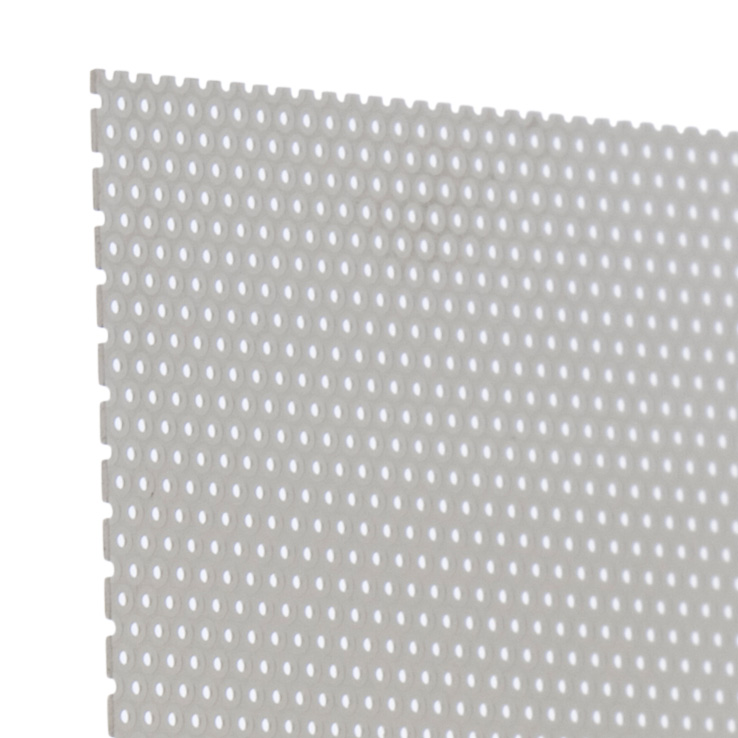

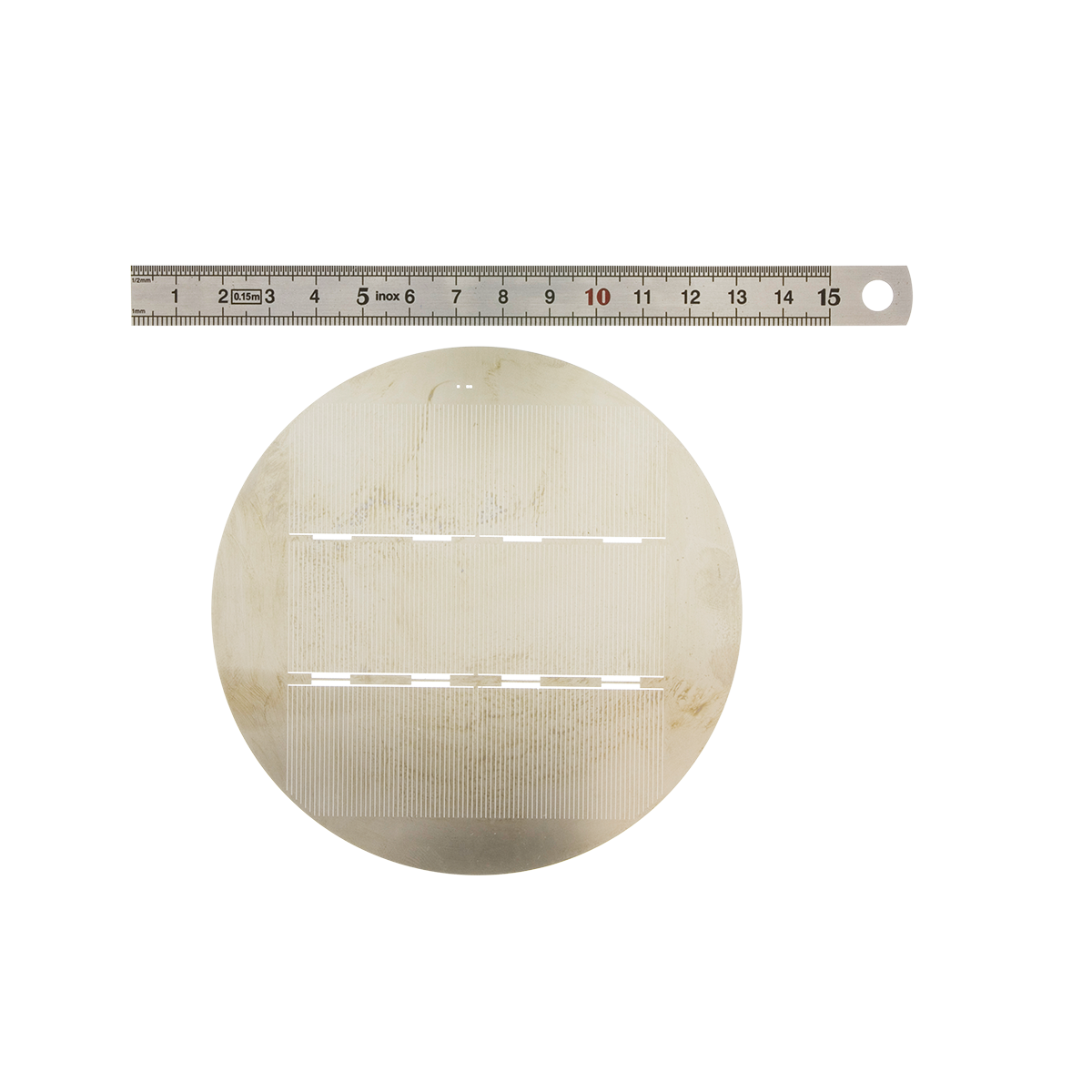

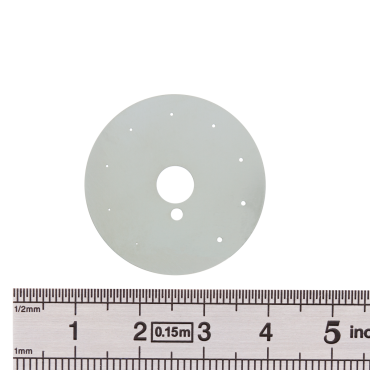

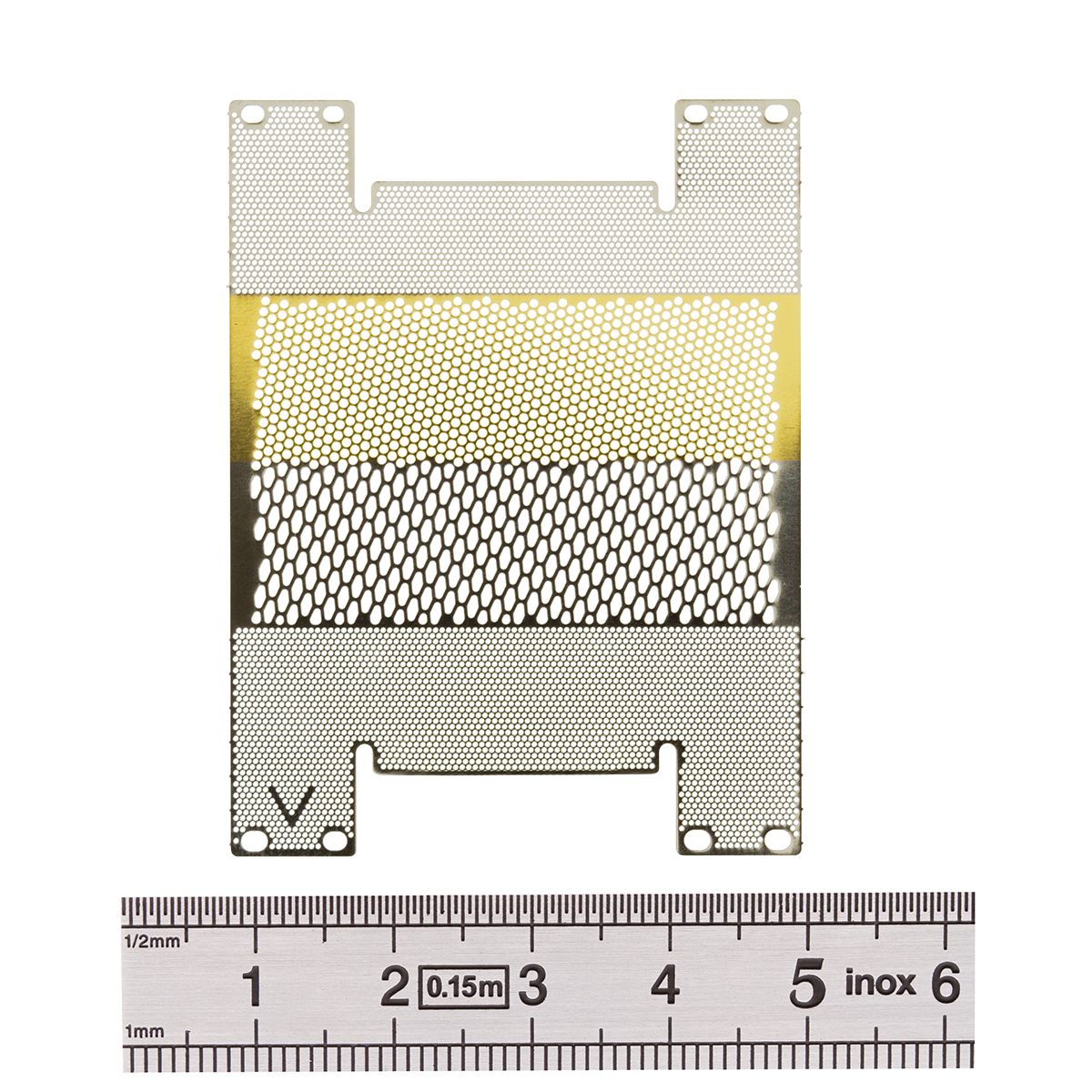

Micron-sized perforations

VECO manufacturing processes allows holes/perforations to be made as small as you wish. You will be able to get over the usual difficulty of making perforations that are smaller than the thickness of the metal. We make metal sheets with holes of diameters down to 0.002mm (i.e. 2 µm).

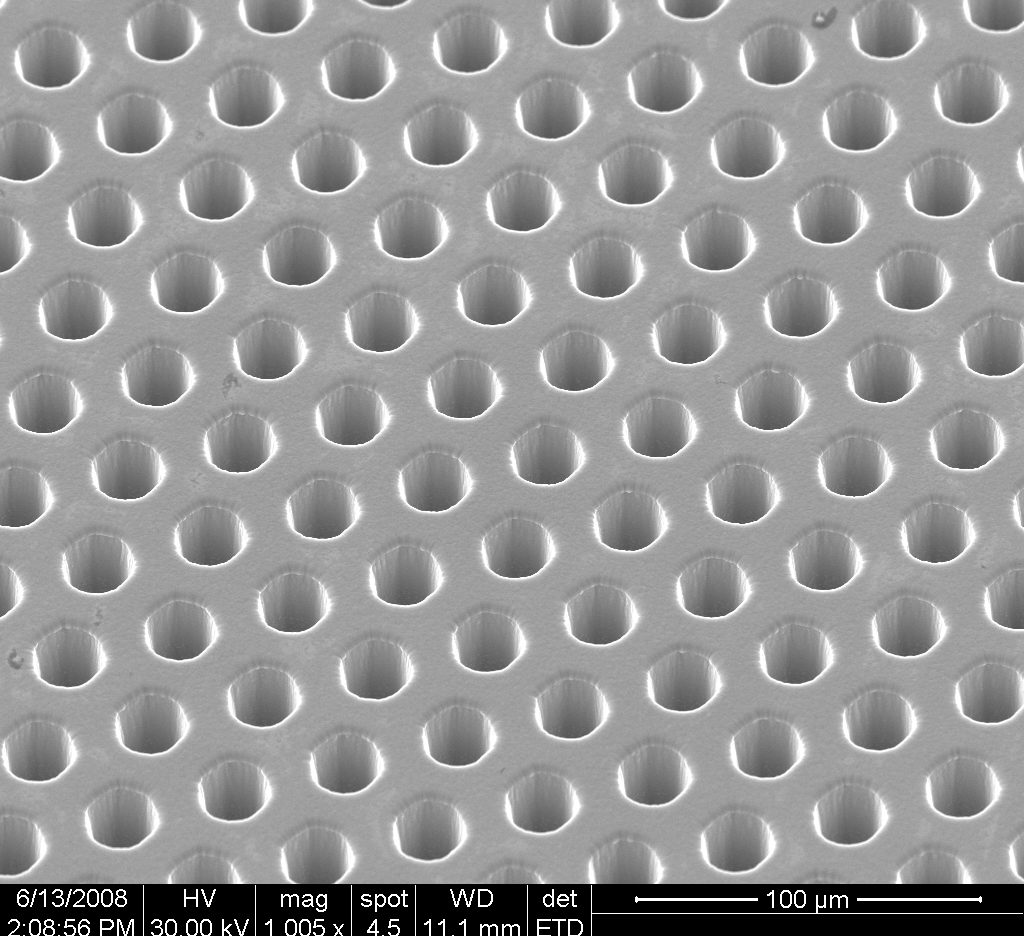

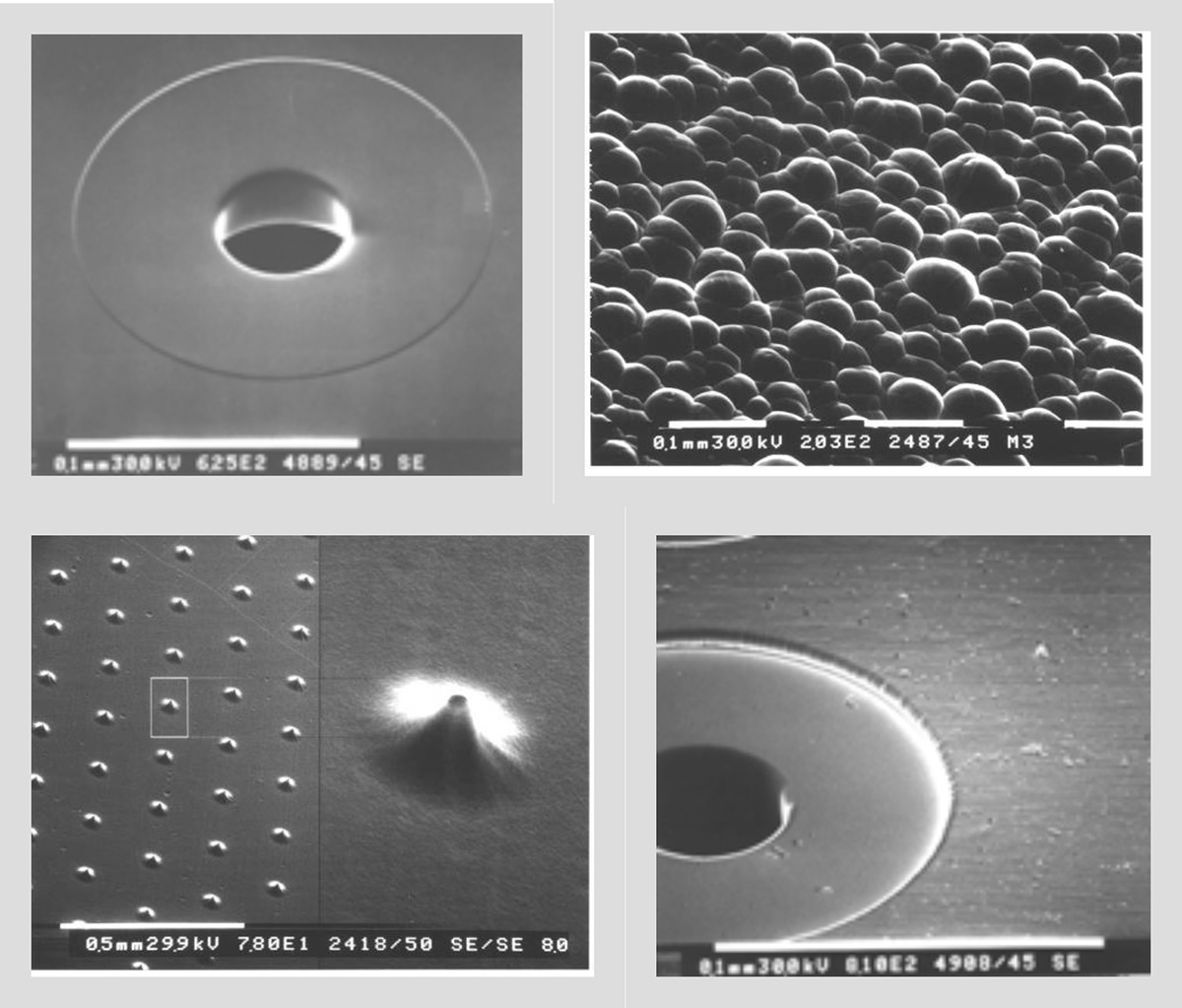

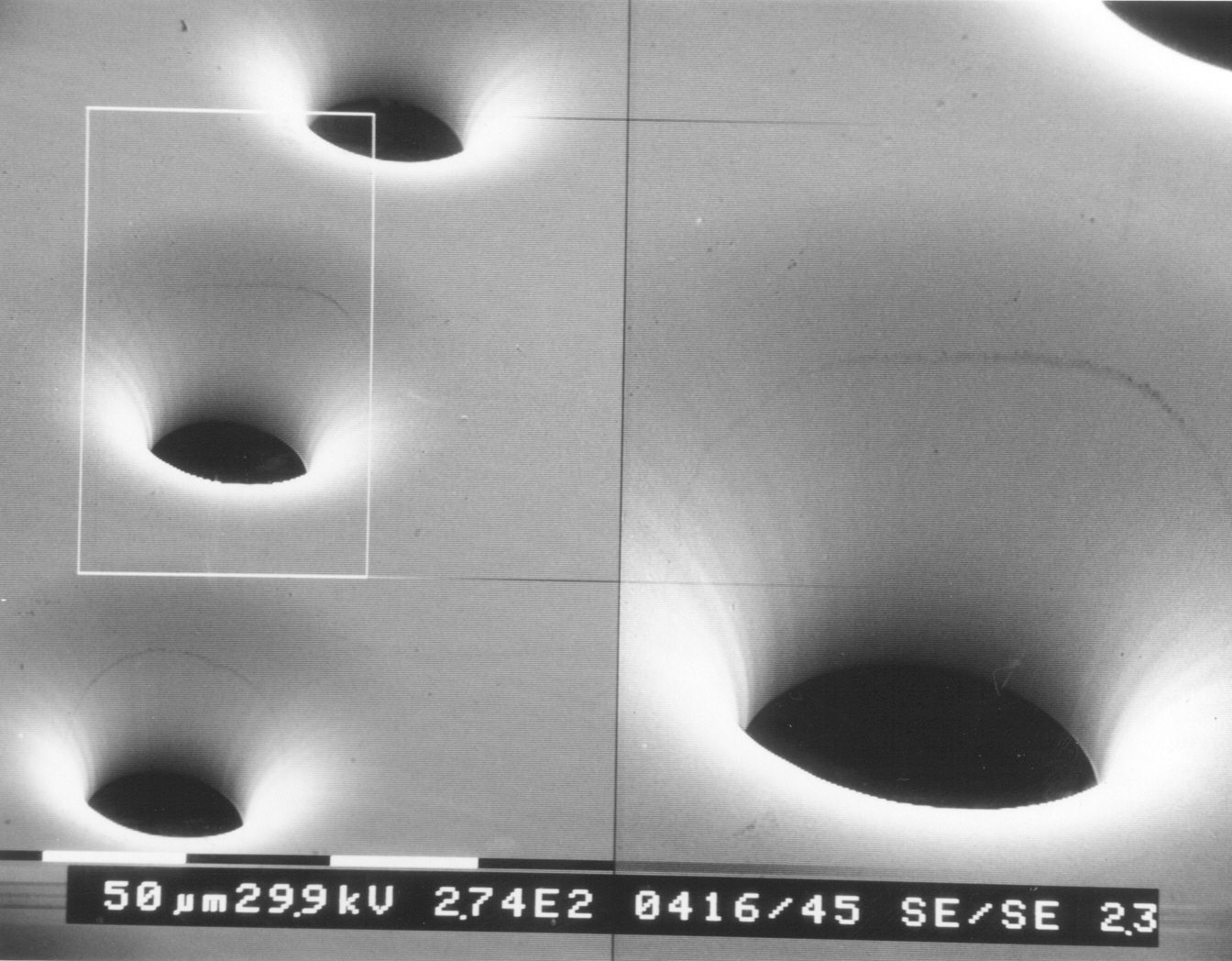

Tapered perforations

Electroforming allows us to make holes with tapered cross-sections. If you look at the cross-section in the thickness of a sheet perforated with holes, the diameter of the hole increases as you cross the metal. The output of the hole is very much greater than that at the entrance. The opening flares. This is very useful in filtration as electroformed filtering media clog up much less than traditional media.

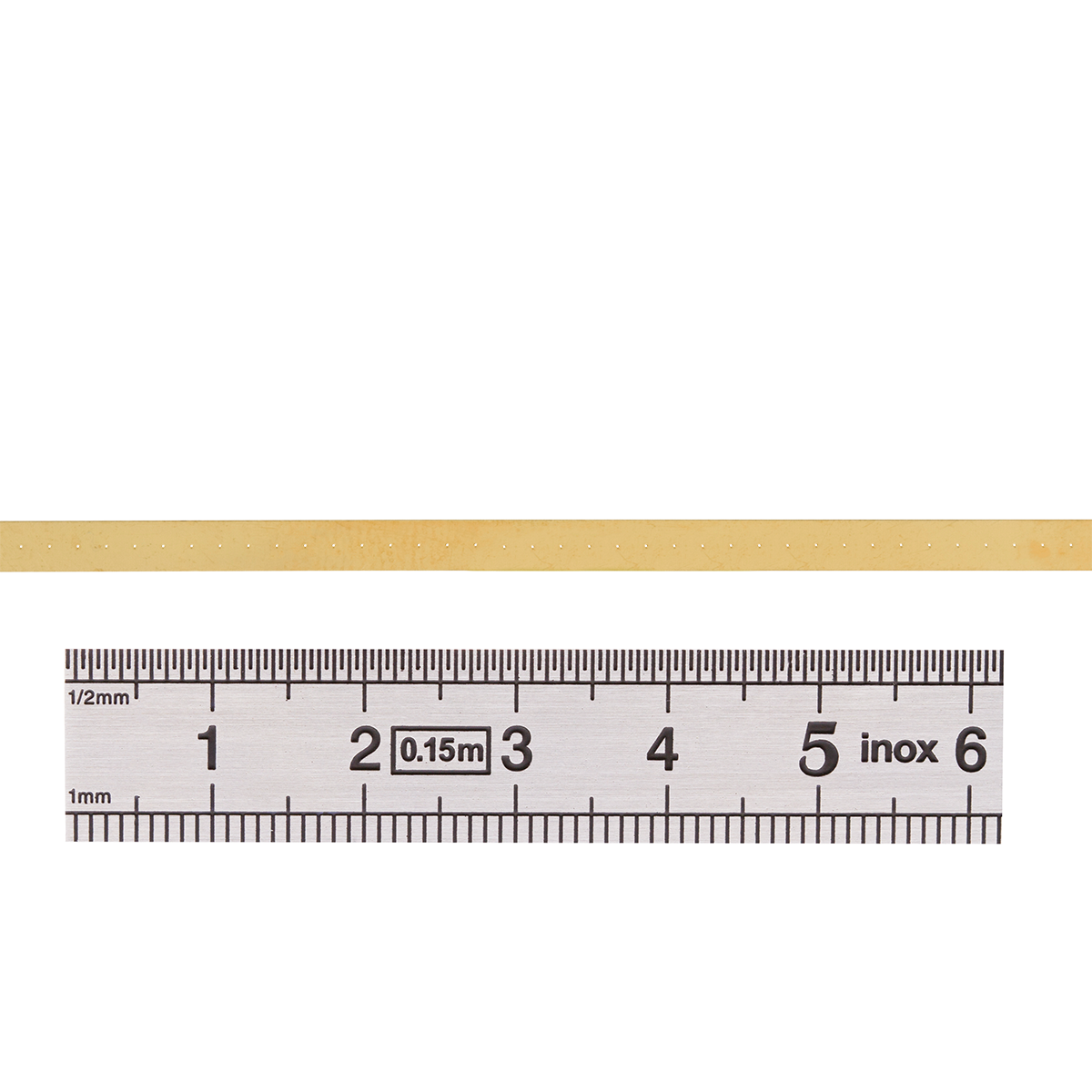

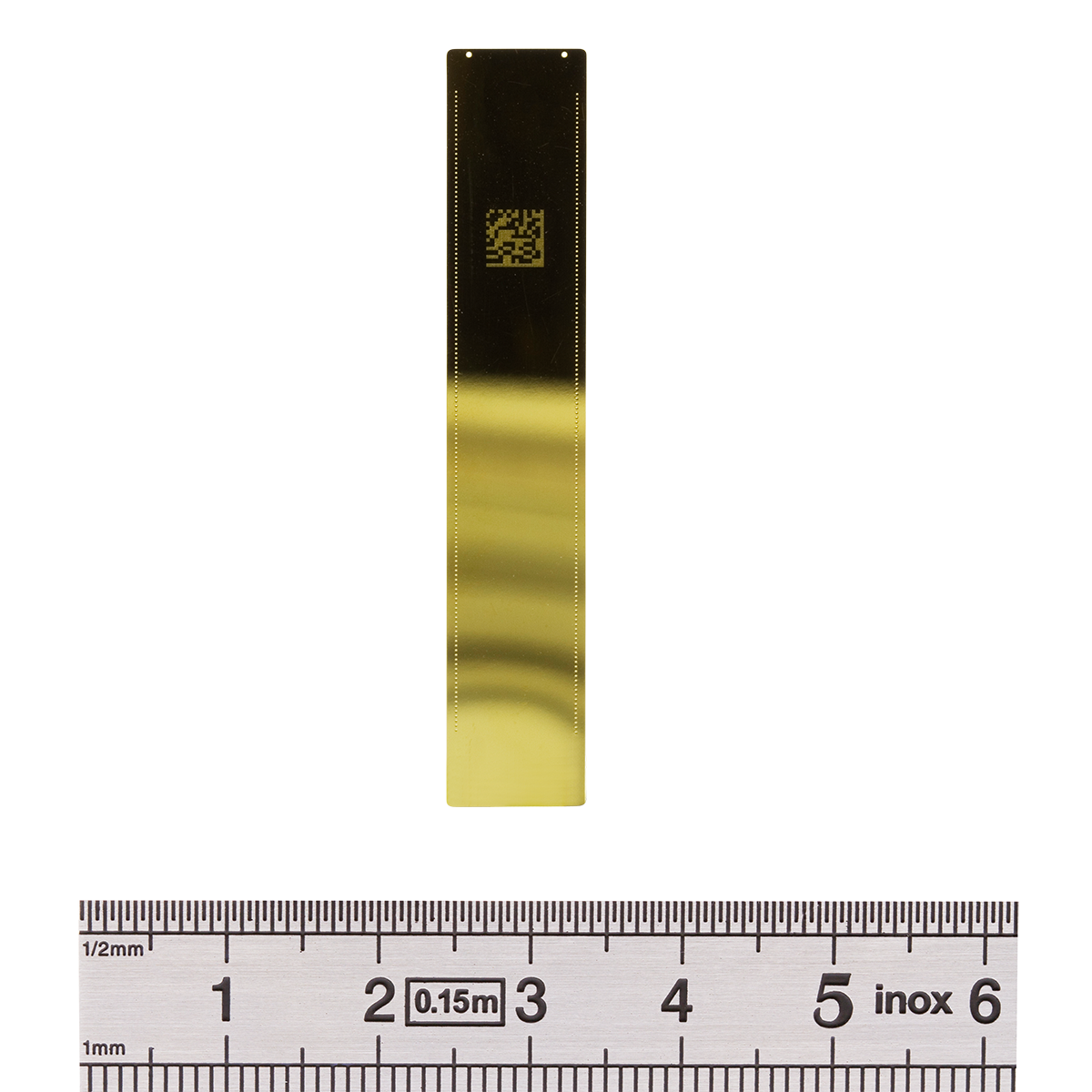

Metal parts low thickness

Chemical cutting and etching and electroforming allow very thin parts to be created and cut. We know how to cut parts with a thickness of 20µm and to create even thinner parts.

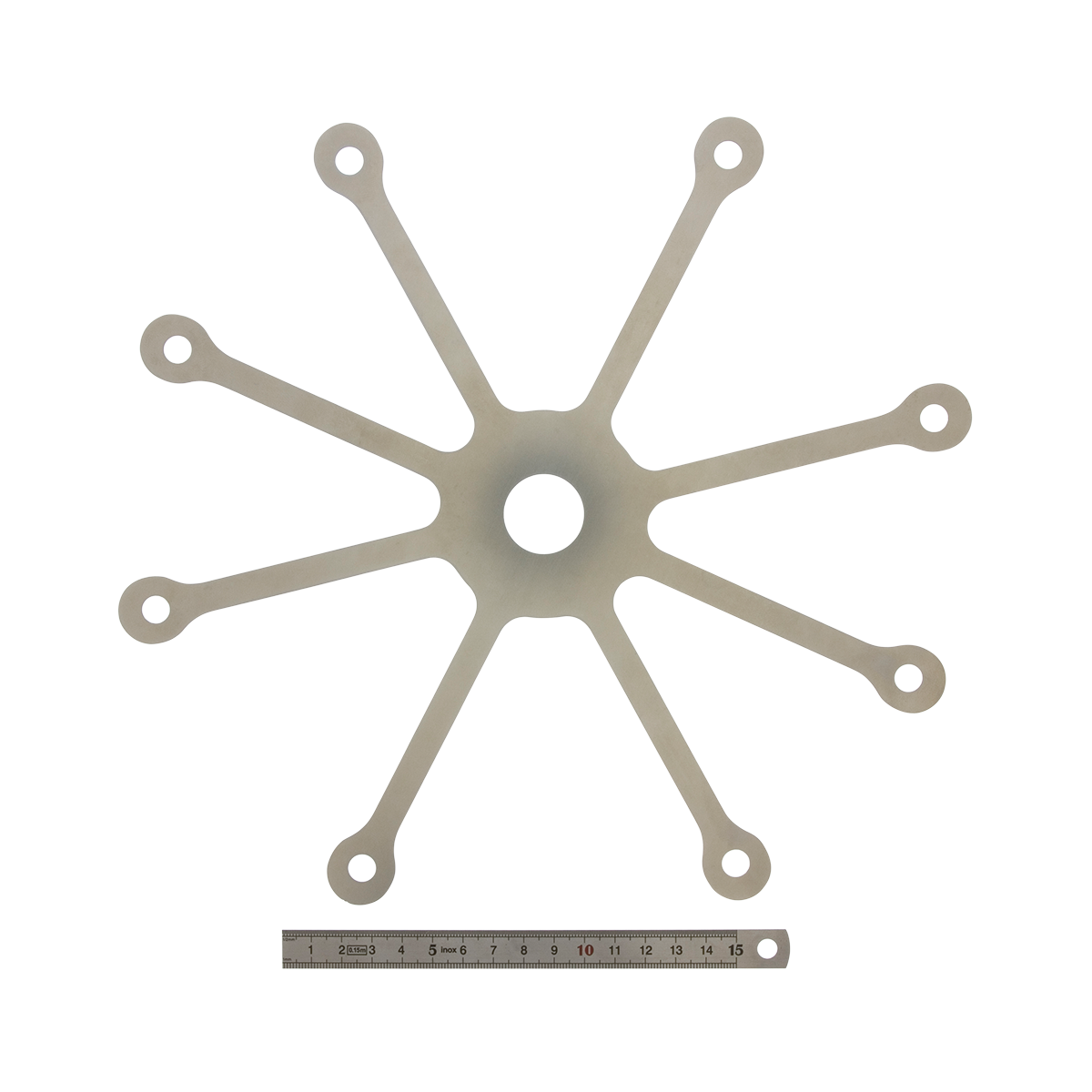

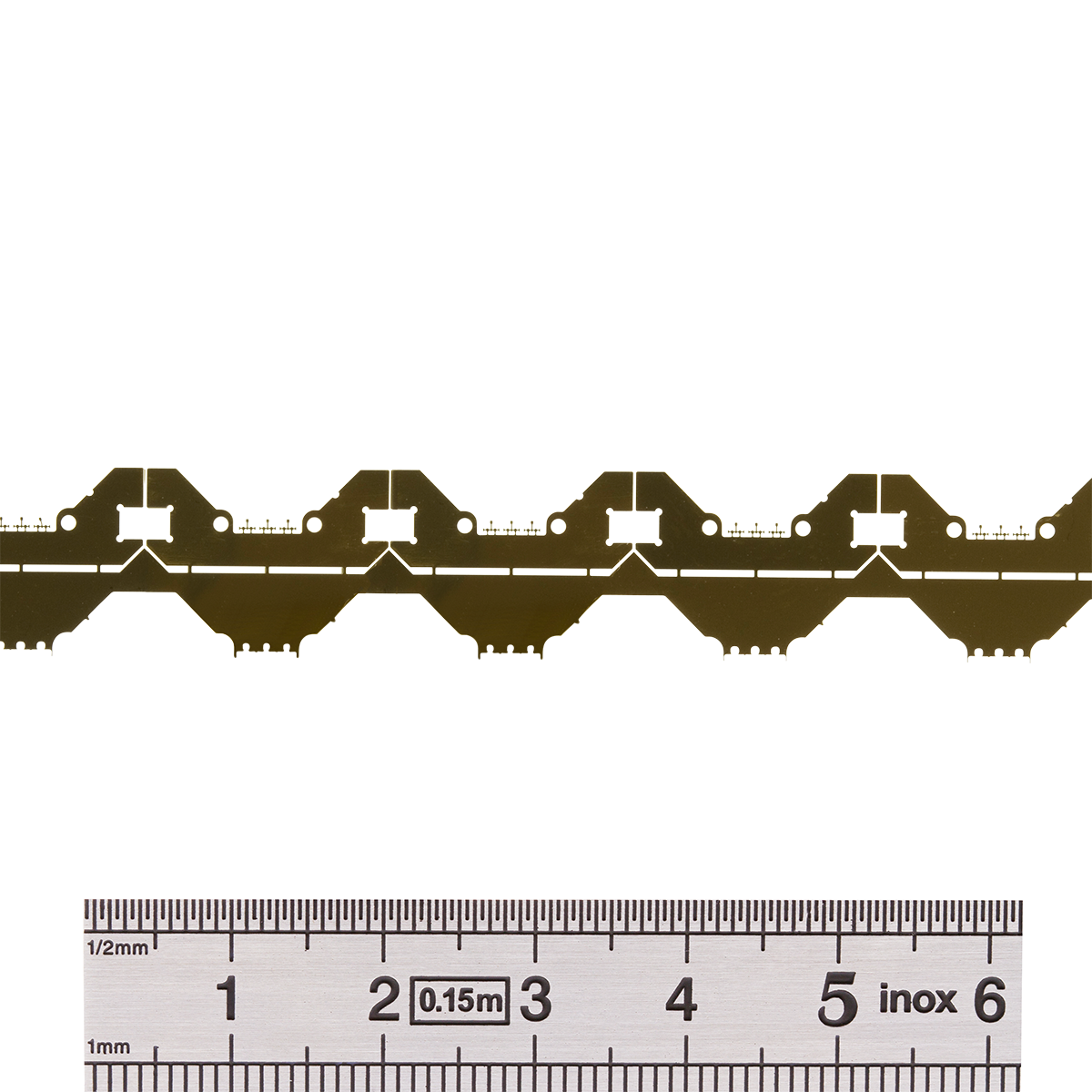

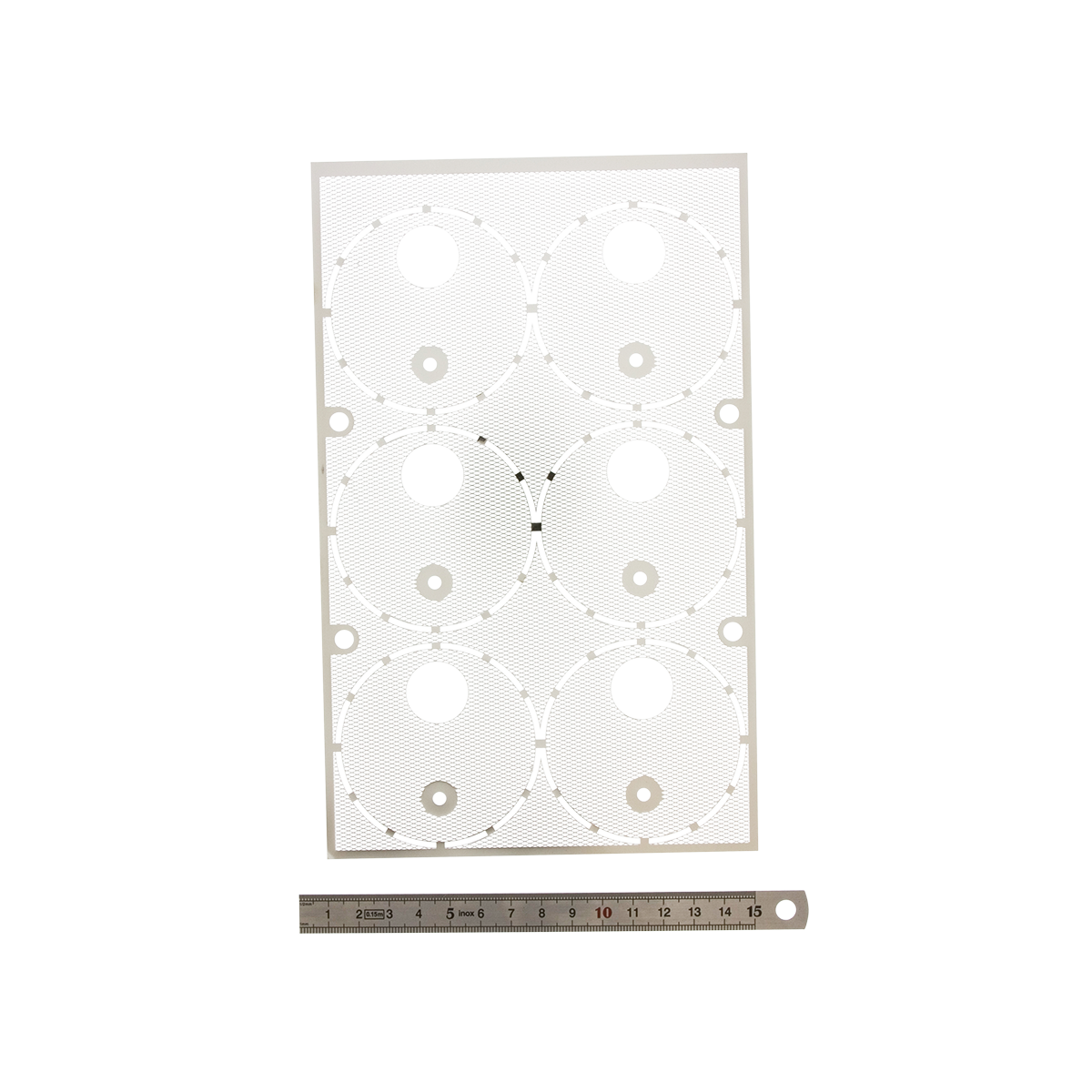

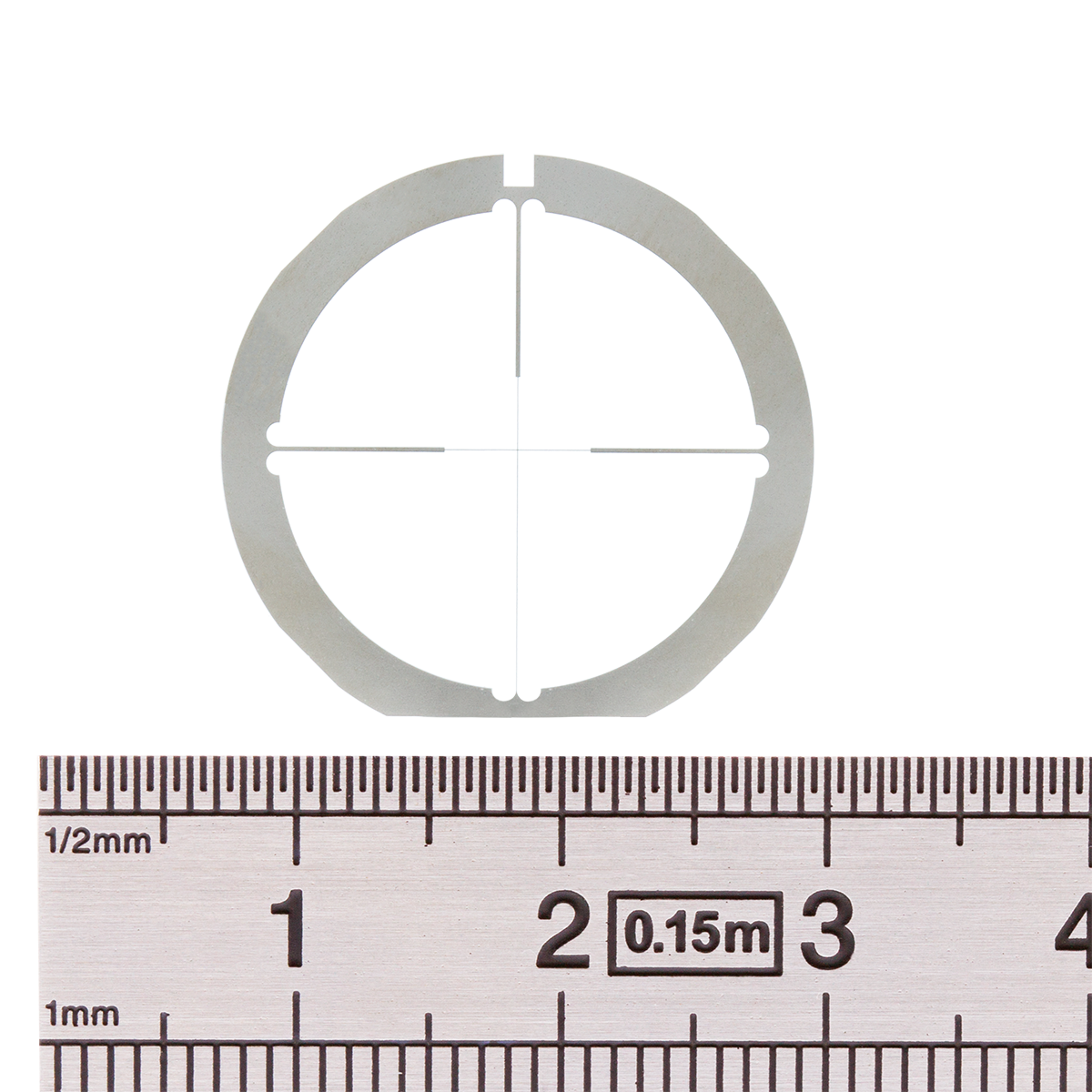

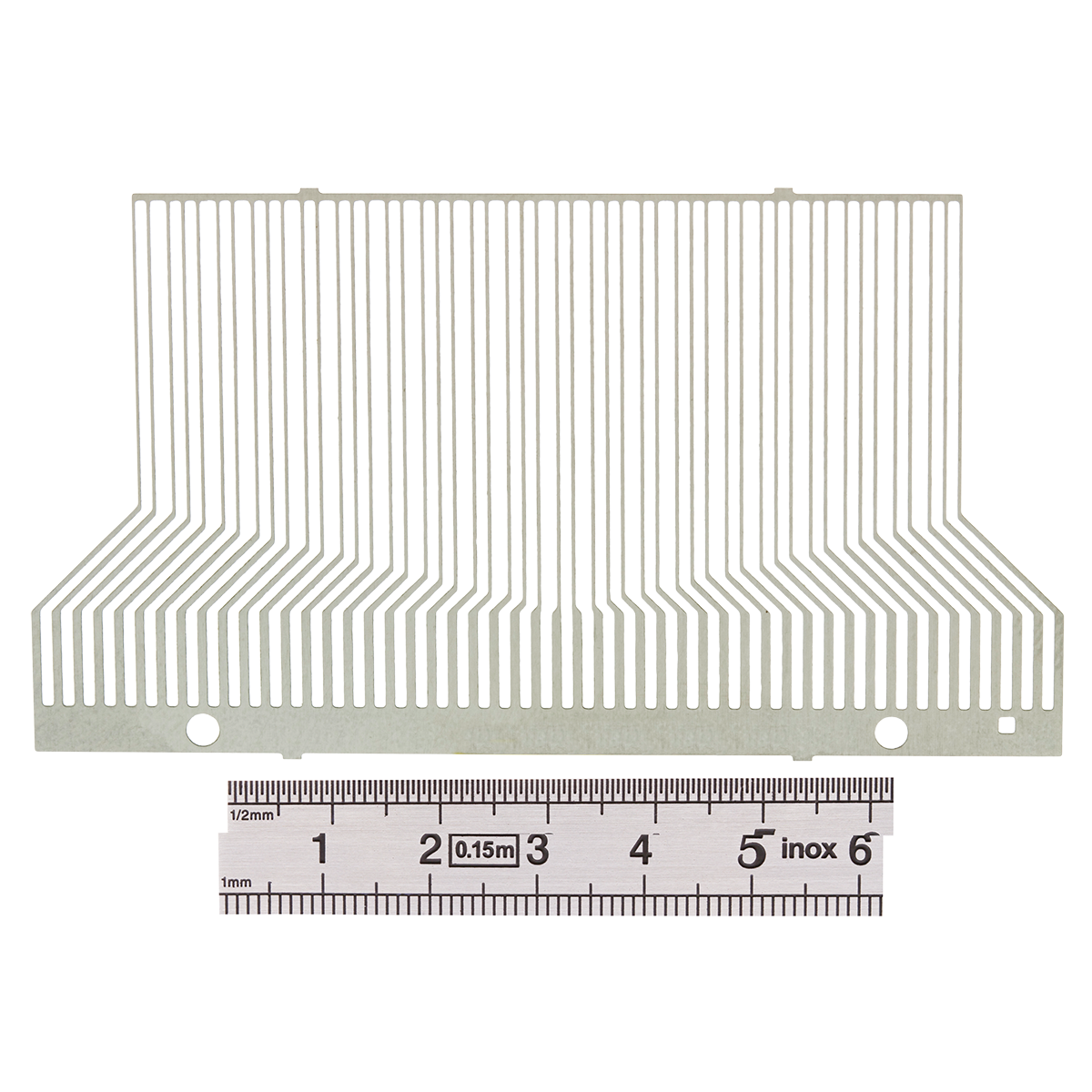

Complex shapes

With electroforming and photochemical cutting, you can let you imagination loose. We are used to saying that if you know how to draw it flat, in most cases we will know how to make it. The complexity of the shape of your metal part has little influence on its price. Unlike classic laser or water jet cutting or stamping, technologies in which the parts are produced one after another, our technologies allow multiple parts to be produced in parallel. Chemical cutting and electroforming do not require costly tools and offer production times with very interesting production costs.

Micrometre tolerances

With chemical cutting we obtain tolerances on the order of ±10% of the thickness (variable and non-linear with the thickness of the metal to cut). In electroforming we can achieve tolerances of ±5 microns or even less than a micron in certain cases.

Absence of stress/cracks

Chemical cutting does not create any mechanical or thermal stress in the parts to produce. It can also be crucial not to have any initiating cracks (cracking, mechanical fragility) in a part. Chemical cutting guarantee you the non-alteration of the mechanical properties of the initial metal. With electroforming it is the same: the parts are naturally flat and without internal stress since they are « created » by electrolytic growth on a perfectly flat matrix. There is no initiating cracking.

Burr free / perfect edges

End of essential deburring! The edges of your electroformed parts are perfect, free from burrs or roughness coming out of production. The definition of the edges of chemically cut parts is greatly superior to a laser (or water jet) cut which produces burned, lacy and very irregular edges when you look at them under high magnification.

Thin tabs / Precise, fine patterns

The fineness of patterns that can be created whether by electroforming or by chemical cutting is impressive. It is possible to produce patterns (bars/wires) of 25µm in width.

Surface replication

L’électroforming allows the surface state of a part to be replicated.

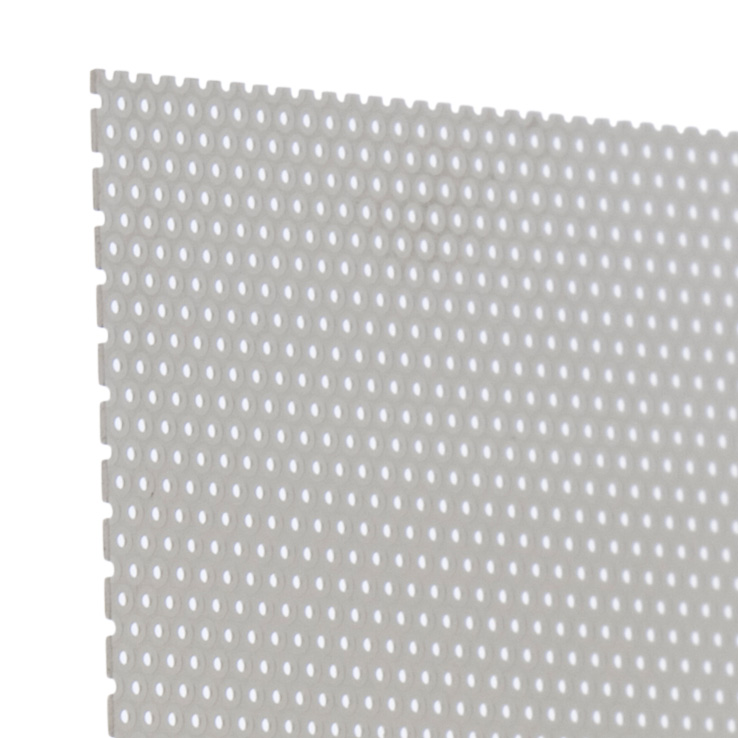

Perforation density

You need a large quantity of holes? This could seem very expensive by traditional technologies, and indeed very complicated. However, by means of chemical cutting and even more by electroforming, it becomes possible to achieve very high hole or perforation densities. We make electroformed micro-perforated sheets with up to 1600 holes /mm2 in the case of laboratory sieves with holes of 5 microns. Choose the perforation density (or the Mesh, i.e. the number of holes per inch (25.4mm) and their distribution and we will be able to produce it.

Français

Français English

English